Research and development activities:

- Weldability of steel in underwater conditions

- Studies of friction stir welding (FSW) processes

- Research on environmental embrittlement of metals and their welded joints

- Corrosion tests of metals and welded joints

- Weldability assessment

- Influence of diffusible hydrogen content in deposited metal on the mechanical properties of welded joints

- Explosive welding process

- Multidimensional analyzes in welding engineering

- Basic research in the field of: theory of thermal processes in welding, theory of welding stresses and deformations, brittle and delayed cracks, theoretical foundations and technologies of explosive welding

- Computer-aided design of welding technology

- Non-destructive tests of welded structures and casts by visual test (VT), penetrant test (PT), magnetic particle test (MT), radiographic test (RT), traditional ultrasonic test (UT), TOFD and Phassed Array

- Design of welding processes

- Automation and robotization of welding processes

- Design of welded structures made of corrosion-resistant steels

- Design and production of fibrous composites with a polymer matrix modified with nanoparticles

- Design and production of surface layers with increased resistance to influence of the aquatic environment (also modification with nanoparticles)

- Expertise opinions on damage of metal materials and welded structures

- Degradation assessment of materials working at high temperatures

- Determining the mechanical properties of engineering materials, especially welded joints:

- Tensile strength tests

- Hardness measurements

- Metallographic tests

- Charpy impact tests – also at lower temperatures (-20 i -40°C)

- Environmental aging in a climatic chamber (180°C / -40°C) with adjustable humidity

- Corrosion resistance tests of metals and welded joints:

- Slow Strain Rate Tensile tests

- Constant Load tests

- Assessment of diffusible hydrogen content in deposited metal

- Impact resistance tests with the use of an INSTRON CEAST 9130 drop hammer

- Determining the susceptibility to cold cracking on the basis of technological tests and the implant test

- Qualification of welding technology, also in underwater conditions

- Certification of divers-welders in accordance with PN-EN ISO and AWS standards

- Quality supervision of welded structures

- Expertise opinions and consulting of welding technologies of structires by EN ISO, ASME, AWS requirements

- Regeneration technologies of machine elements

Training offer:

Postgraduate studies - International Welding Engineer IWE I, IWE II, IWE III Authorized Training Center of the International Institute of Welding.

Apparatus available at the Department laboratories:

- SAW welding device ESAB A2 Multitrac + welding power source 1000A

- MIG/MAG + MMA ESAB Aristo Mig 4004 Pulse device

- TIG AC-DC ESAB Caddy Tig 2200i device

- Plasma cutting and gouging device ESAB PowerCut 1600

- Devices for resistance (spot and butt) welding, friction welding and friction stir welding (FSW) also in water environment

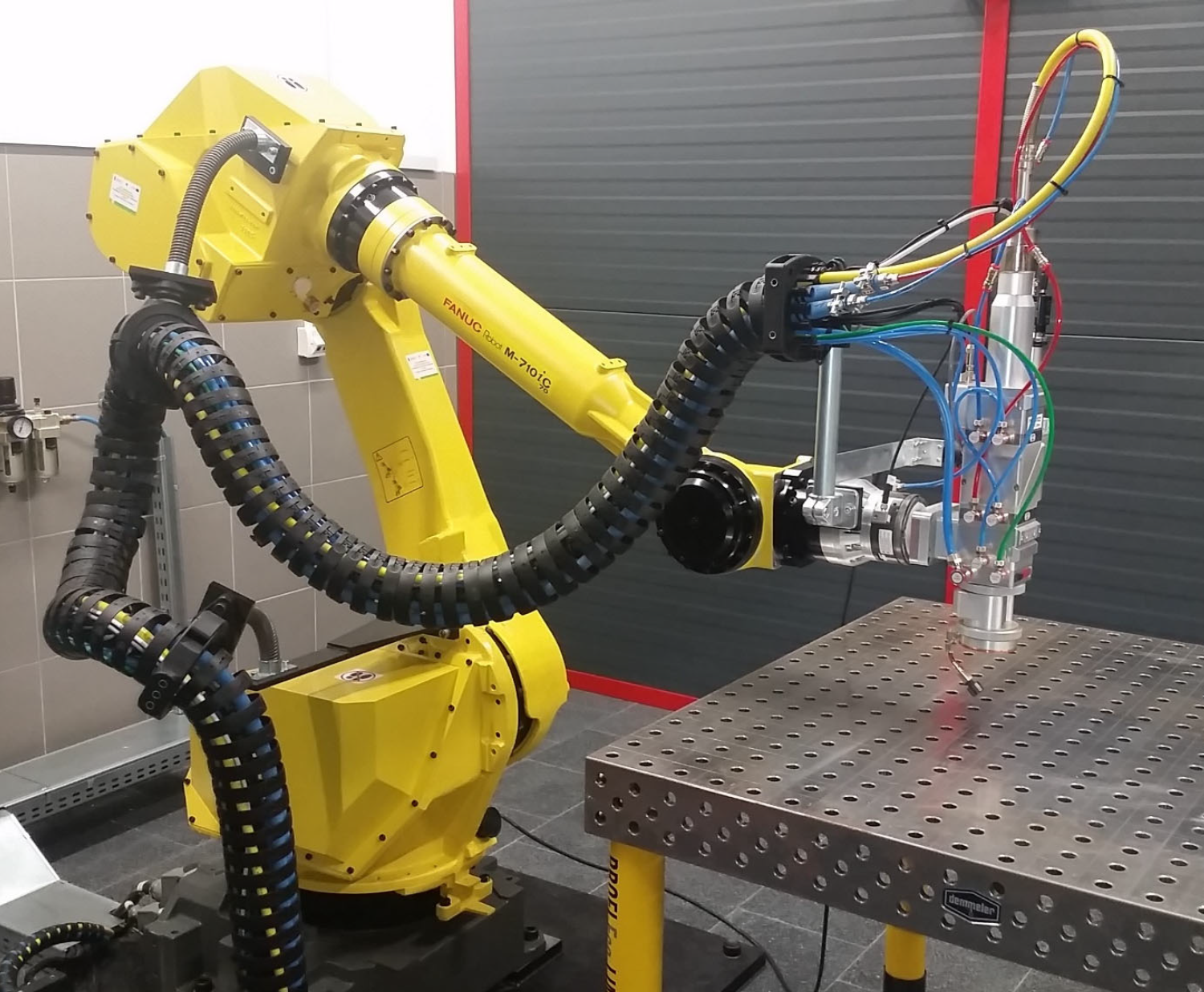

- Fiber laser for welding IPG – YLS-6000 with Fanuc M710 robot

- Defectoscopes OMNISCAN MX: OLYMPUS, EPOCH1000i (GE - OLYMPUS), PHASOR XS (Krautkramer)

- Radiographic chamber, RTG Picker Andrex 3001 (300kV) aparatus

- Stands for testing stress corrosion cracking (SSRT, CL)

- Bruker diffusible hudrogen content measurement stand

- Resistance furnace for heat treatment

- Metal forming devices:

- hydraulic press,

- mechanical press,

- cutting stand,

- roll forming device,

- drawing device.

Cooperation with companies:

NST, Kobelco, Lincoln Electric, Kemppi, Esab, Marszal, Figel, Messer, Linde, Nauta Shipyard, Crist Shipyard, Gdańsk Shipyard, Lotos, TTU, Hexonic, Polmor

Exemplary scientific publications:

- Świerczyńska A., Fydrych D., Rogalski G.: Diffusible hydrogen managment in underwater wet self-shielded flux cored arc welding. International Journal of Hydrogen Energy, 2017, 42(38), 24532-24540.

- Tomków J., Rogalski G., Fydrych D., Łabanowski J.: Improvement of S355G10+N steel weldability in water environment by Temper Bead Welding. Journal of Materials Processing Technology, 2018, 262, 372-381.

- Świerczyńska A., Fydrych D., Landowski M., Rogalski G., Łabanowski J.: Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection. Construction and Building Materials, 2020, 238, 117697.

- Tomków J., Fydrych D., Rogalski G.: Dissimilar underwater wet welding of HSLA steels. The International Journal of Advanced Manufacturing Technology, 2020, 109, 717-725.

- Tomków J., Landowski M., Fydrych D., Rogalski G.: Underwater wet welding of S1300 ultra-high strength steel. Marine Structures, 2022, 81, 103120.