Date added: 2021-10-14

Everything can be measured here. A modern Metrology Lab has been opened at the FMEST

Laboratory was launched - with a symbolic cutting of the ribbon - by GUT Rector, professor Krzysztof Wilde, PhD, DSc, ME, FMEST Dean professor Andrzej Seweryn, PhD, DSc, ME and vice-president of Mitutoyo company - Jakub Ruszkowski.

– The measuring devices and apparatus can be applied in automotive, aviation and medical industry, to mention but a few, where transparent, reliable and repeatable results that can be achieved quickly are of utmost importance - says professor Krzysztof Wilde, rector of the GUT.

Cooperation between science and industry

– The arrangement of our faculty and Mitutoyo company is a perfect example of cooperation between the world of science and industry - professor Andrzej Seweryn said during the event - both parties want this cooperation to develop and bring substantial effects.

– Laboratories, equipment, our knowledge and experience in metrology will serve the GUT staff in order to conduct advanced research here. We want to invest in youth, so that they can gain practical knowledge, have access to advanced technology and learn things that are necessary in the industry - said Jakub Ruszkowski, vice-president of the board of Mitutoyo Polska, who also happens to be a GUT graduate.

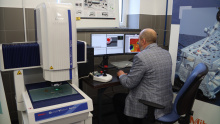

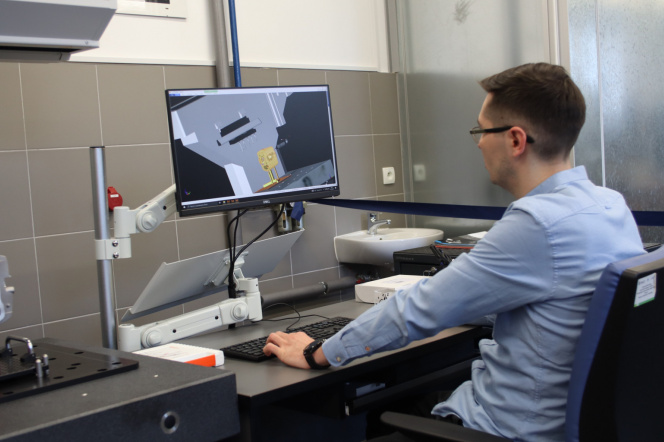

– Our staff and students will have access to the newest technology available in metrology. In the lab we will be able to conduct a complex analysis of the geometrical precision of products which is very helpful in scientists' research - says Michał Dobrzyński, PhD, ME, head of the laboratory.

State-of-the art equipment

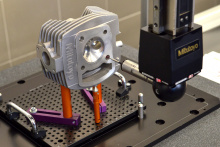

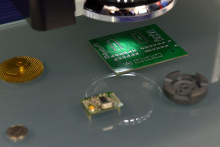

Optical 2D and 3D measurement systems and CMM machines (coordinate measuring machines) are only a few of the new devices given to GUT by a Japanese company Mitutoyo to be used by GUT staff and students. Altogether, there are five new devices in the laboratory:

1. QUICK IMAGE – 2D optical measurement systems allowing measurements of products on multiple planes at the same time without the need for separate focusing.

2. QUICK VISION – 3D optical measurement systems for fully-automated quick measurements.

3. CONTRACER SV-C3200 – intelligent combination of two stationary devices: contour tracer and surface roughness tester. A single device for reliable measurements of contours and surface roughness.

4. CMM Crystal-Plus M – manual, economy coordinate measuring machines for 3D measurements. Used for quick but precise shop-floor measurement, featuring precise positioning of the probe and automatic element recognition system, facilitating the operation of the device.

5. Mitutoyo MiSTAR 555 – a compact, coordinate measuring CNC machine operated in a production hall. It combines automated measurement with flexibilty, reliability and simplicity of operation.

Mitutoyo is one of the largest providers of metrology equipment in the world. It conducts R&D, production and distribution activities in more than 100 countries. Mitutoyo Polska was launched in 2002 and offers state-of-the-art measurement devices and metrology solutions.

The laboratory is worth about PLN 1.5 million.